The Growing Need for PVC Stabilizers in Pakistan

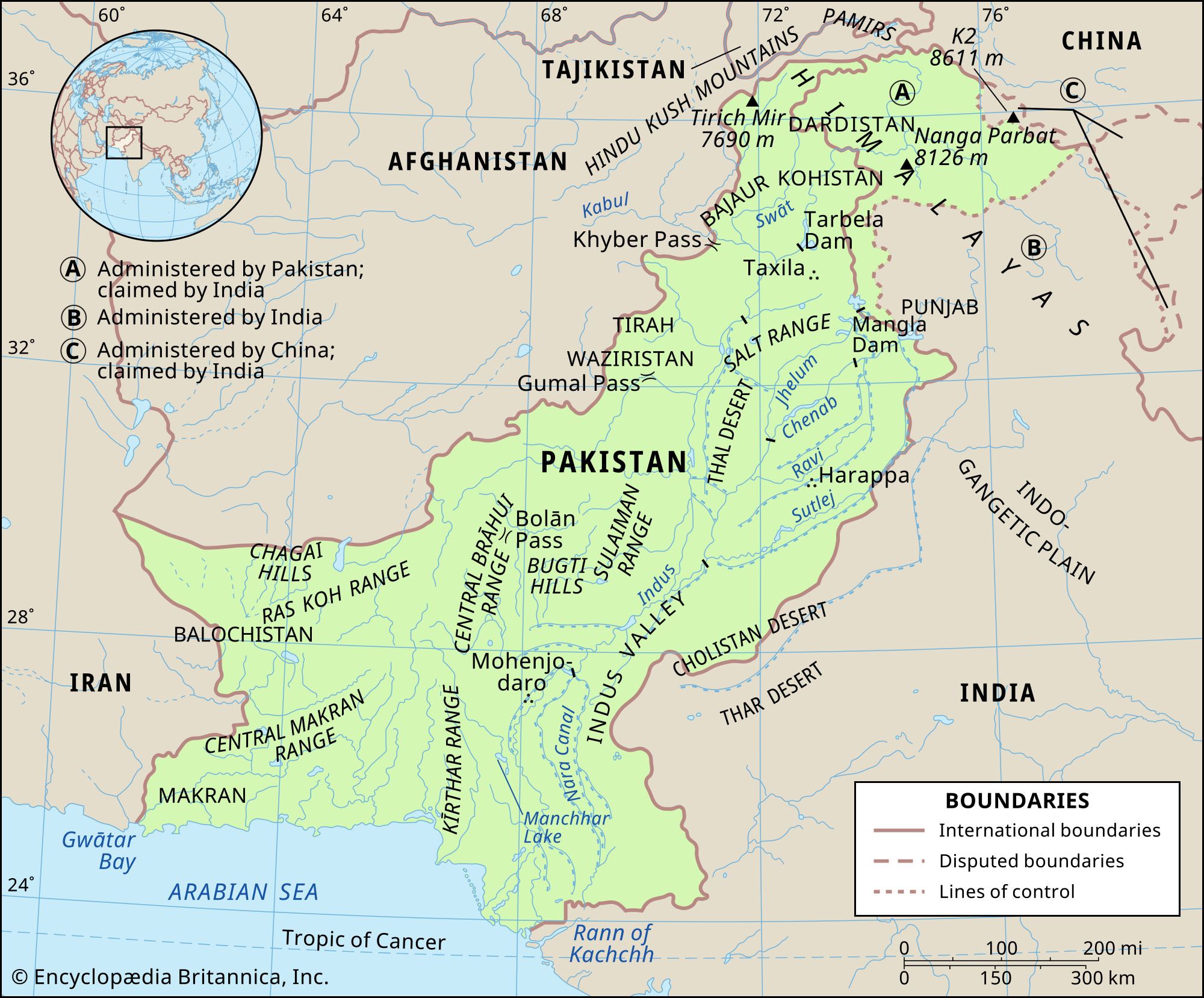

Pakistan map

Polyvinyl chloride (PVC) is a versatile and widely used polymer in various industries, from construction to healthcare. In Pakistan, the demand for PVC products has been steadily increasing, driven by rapid urbanization, infrastructure development, and industrial growth. However, to ensure the durability and safety of PVC products, the use of PVC stabilizers is essential. This article explores the growing need for PVC stabilizers in Pakistan, their applications, and the benefits they bring to various sectors.

The Role of PVC Stabilizers

PVC stabilizers are additives that enhance the thermal stability and processing characteristics of PVC. They prevent the degradation of PVC during processing and extend the lifespan of the final products by protecting them from heat, UV radiation, and chemical reactions. In Pakistan, the use of PVC stabilizers is crucial for several reasons:

Infrastructure Development: Pakistan is witnessing significant infrastructure development, including the construction of roads, bridges, and buildings. PVC pipes and fittings are extensively used in these projects due to their durability and cost-effectiveness. PVC stabilizers ensure that these products can withstand harsh environmental conditions and maintain their integrity over time.

Water Supply and Sanitation: The country’s growing population and urbanization have increased the demand for reliable water supply and sanitation systems. PVC pipes, which are commonly used for water distribution and sewage systems, require stabilizers to prevent degradation and ensure long-term performance.

Electrical and Electronics Industry: PVC is widely used in the electrical and electronics industry for cable insulation and sheathing. Stabilizers are essential to protect these products from heat generated by electrical currents, ensuring safety and longevity.

Healthcare Sector: In the healthcare sector, PVC is used in medical devices, tubing, and packaging. Stabilizers play a vital role in maintaining the safety and effectiveness of these products, which are often exposed to sterilization processes and various chemicals.

Challenges and Opportunities

While the need for PVC stabilizers in Pakistan is evident, there are challenges that need to be addressed:

Cost of Raw Materials: The cost of raw materials for PVC stabilizers, such as lead sulfate, can be high. This impacts the overall cost of PVC products and can be a barrier for manufacturers.

Environmental Concerns: There is a growing awareness of the environmental impact of certain stabilizers, particularly those containing heavy metals. This has led to a shift towards more environmentally friendly alternatives, such as calcium-zinc stabilizers.

Regulatory Compliance: Ensuring compliance with international standards and regulations is essential for the export of PVC products. Manufacturers need to adopt stabilizers that meet these standards to remain competitive in the global market.

Conclusion

The need for PVC stabilizers in Pakistan is driven by the country’s rapid development and the increasing demand for durable and safe PVC products. While there are challenges to overcome, such as the cost of raw materials and environmental concerns, the benefits of using PVC stabilizers far outweigh these challenges. By adopting advanced stabilizer technologies and ensuring regulatory compliance, Pakistan can continue to meet its growing demand for high-quality PVC products, contributing to the country’s overall economic growth and development.

Tap here for more info