Rigid PVC Compounds

In the realm of modern materials, rigid Polyvinyl Chloride (PVC) compounds stand out for their versatility and durability. These compounds are integral to various industries, notably in construction and footwear manufacturing. This article delves into the properties of rigid PVC compound, their applications in sneaker making and building construction, and the benefits they offer.

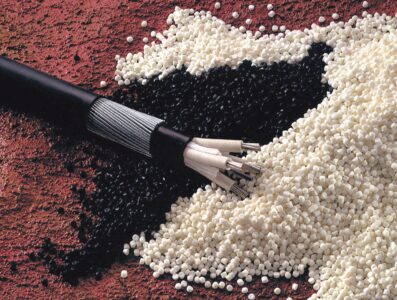

Rigid PVC compound

Properties of Rigid PVC Compounds

Rigid PVC, or unplasticized PVC, is a marvel of material science. It is manufactured by polymerizing vinyl chloride monomers, resulting in a strong, durable, and weather-resistant thermoplastic polymer. Unlike its plasticized counterpart, rigid PVC does not contain plasticizers, which means its polymer chains are closely packed, giving it its characteristic rigidityAd.

The key properties of rigid PVC include:

High Mechanical Strength: Rigid PVC is known for its robustness, capable of withstanding significant stress without deformation.

Excellent Chemical Resistance: It resists a wide array of chemicals, making it ideal for industrial applications.

Fire Resistance: Rigid PVC is self-extinguishing and does not support combustion, enhancing safety in applications where fire hazards are a concern.

Weather Resistance: It can endure harsh weather conditions, making it suitable for outdoor use.

Rigid PVC in Sneaker Manufacturing

In the footwear industry, rigid PVC has revolutionized sneaker production. It’s used in various parts of the shoe, from insoles to uppers, especially in sportswear. The development of specialized granules with properties like air-permeability, extra cushioning, and high abrasion resistance has significantly improved the performance and comfort of sneakers. Moreover, PVC shoe soles are known for their longevity, as they do not tear or break easily, providing consumers with durable and long-lasting footwear.

Rigid PVC in Building and Construction

The construction industry heavily relies on rigid PVC for its cost-effectiveness and easy installation. It is commonly used in:

Piping Systems: Due to its strength and chemical resistance, rigid PVC is an excellent choice for plumbing.

Window Frames and Sills: Its weather resistance makes it ideal for insulating glazing in new buildings or replacing older windows.

Roofing: Rigid PVC roofing membranes are durable and can remain watertight even in extreme weather conditions.

Siding: Vinyl siding, made from rigid PVC, accounts for about 50% of all residential and light commercial building exteriors due to its durability and ease of maintenance.

Benefits of Rigid PVC Compounds

The benefits of using rigid PVC compounds are manifold:

Cost-Effectiveness: Rigid PVC is less expensive than many other materials, offering economic advantages in large-scale applications.

Low Maintenance: It requires minimal upkeep, reducing long-term costs and effort.

Sustainability: Rigid PVC’s durability means it doesn’t need frequent replacement, contributing to resource conservation.

Design Flexibility: It can be produced in various shapes, sizes, and colors, allowing for creative design solutions.

Conclusion

Rigid PVC compounds are a cornerstone of innovation in both the construction and footwear industries. Their unique properties make them indispensable in creating products that are not only functional and durable but also safe and cost-effective. As technology advances, we can expect rigid PVC to continue playing a pivotal role in the development of new and improved materials for a variety of applications.