Africa’s Need for Polyethylene Wax

Africa’s map polyethylene Wax

Africa, a continent rich in resources and potential, is experiencing rapid industrialization and urbanization. As various industries expand, the demand for materials that enhance product quality and manufacturing efficiency is on the rise. One such material is polyethylene wax, a versatile additive with numerous applications across different sectors.

The Role of Polyethylene Wax

Polyethylene wax (PE wax) is a low molecular weight polymer derived from ethylene. It is known for its excellent chemical stability, low viscosity, and high melting point, making it an invaluable component in various industrial processes. Its primary applications include:

Plastics Industry: PE wax is widely used as a processing aid and performance enhancer in plastic manufacturing. It improves the flow properties of molten plastic, increases production speed, reduces energy consumption, and enhances the final product’s surface gloss and scratch resistance.

Adhesives and Coatings: In adhesives, PE wax improves the bonding strength and durability. In coatings, it provides a smooth finish and enhances resistance to environmental factors.

Rubber Industry: PE wax acts as a lubricant and processing aid, improving the dispersion of fillers and enhancing the overall quality of rubber products.

Textiles: Emulsions made from PE wax are used to soften fabrics and provide resistance against acids, preventing yellowing and color changes.

khalijpolymer exporting team : we as an exporting team guarantee the quality of our products that’s our priority but we also made sure that prices we offer are lowest possible in international market. we value the time of our costumers Wich we rather call our business partners. You can contact us on WhatsApp. We prefer video call meetings.

Africa’s Industrial Growth and Demand

Africa’s industrial sector is growing at an unprecedented rate. Countries like Nigeria, South Africa, and Kenya are investing heavily in infrastructure, manufacturing, and technology. This growth is driving the demand for high-quality materials that can improve efficiency and product performance.

Infrastructure Development: As African nations invest in building roads, bridges, and buildings, the construction industry requires materials that can withstand harsh environmental conditions. PE wax, used in coatings and adhesives, plays a crucial role in ensuring the durability and longevity of construction materials.

Automotive Industry: The automotive sector in Africa is expanding, with an increasing number of vehicles being manufactured locally. PE wax is essential in the production of high-quality plastic components and rubber parts, contributing to the overall performance and safety of vehicles.

Packaging Industry: With the rise of e-commerce and retail, the demand for packaging materials is soaring. PE wax enhances the quality of plastic packaging, making it more durable and resistant to wear and tear.

Environmental and Economic Benefits

The use of PE wax in various industries not only improves product quality but also offers environmental and economic benefits. By enhancing the efficiency of manufacturing processes, PE wax helps reduce energy consumption and production costs. Additionally, its ability to improve the durability of products means less frequent replacements, leading to reduced waste and a lower environmental footprint.

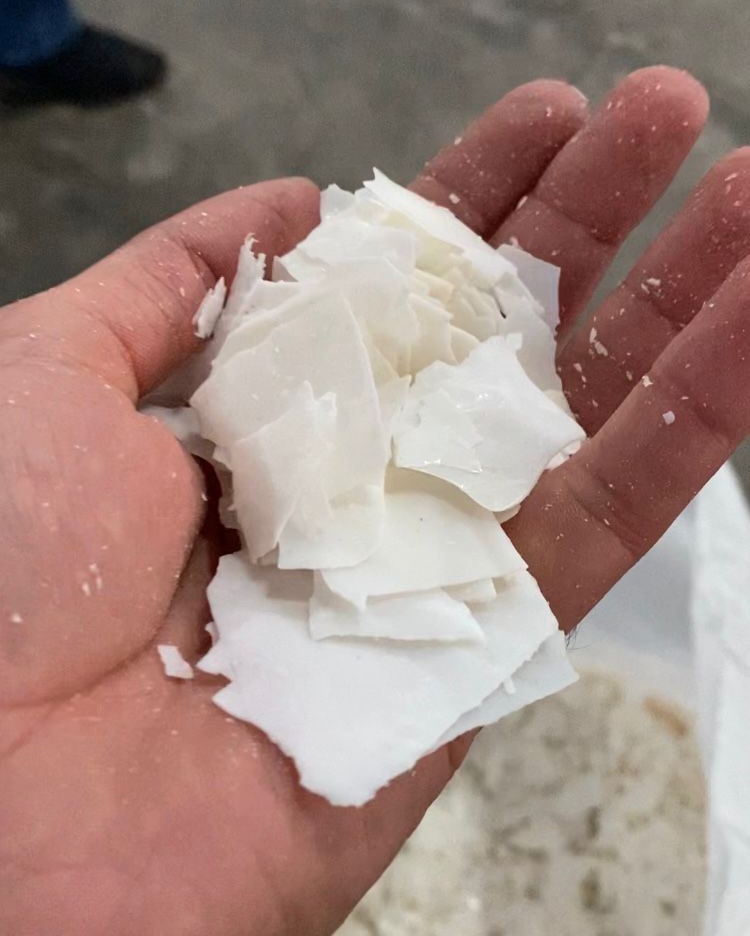

Polyethylene Wax

Conclusion

Africa’s need for polyethylene wax is a reflection of its broader industrial ambitions. As the continent continues to develop, the demand for materials that can enhance efficiency, durability, and performance will only grow. Polyethylene wax, with its versatile applications and significant benefits, is poised to play a crucial role in Africa’s industrial future.

Click here to purchase our products.