The Global Impact of Polyethylene Wax

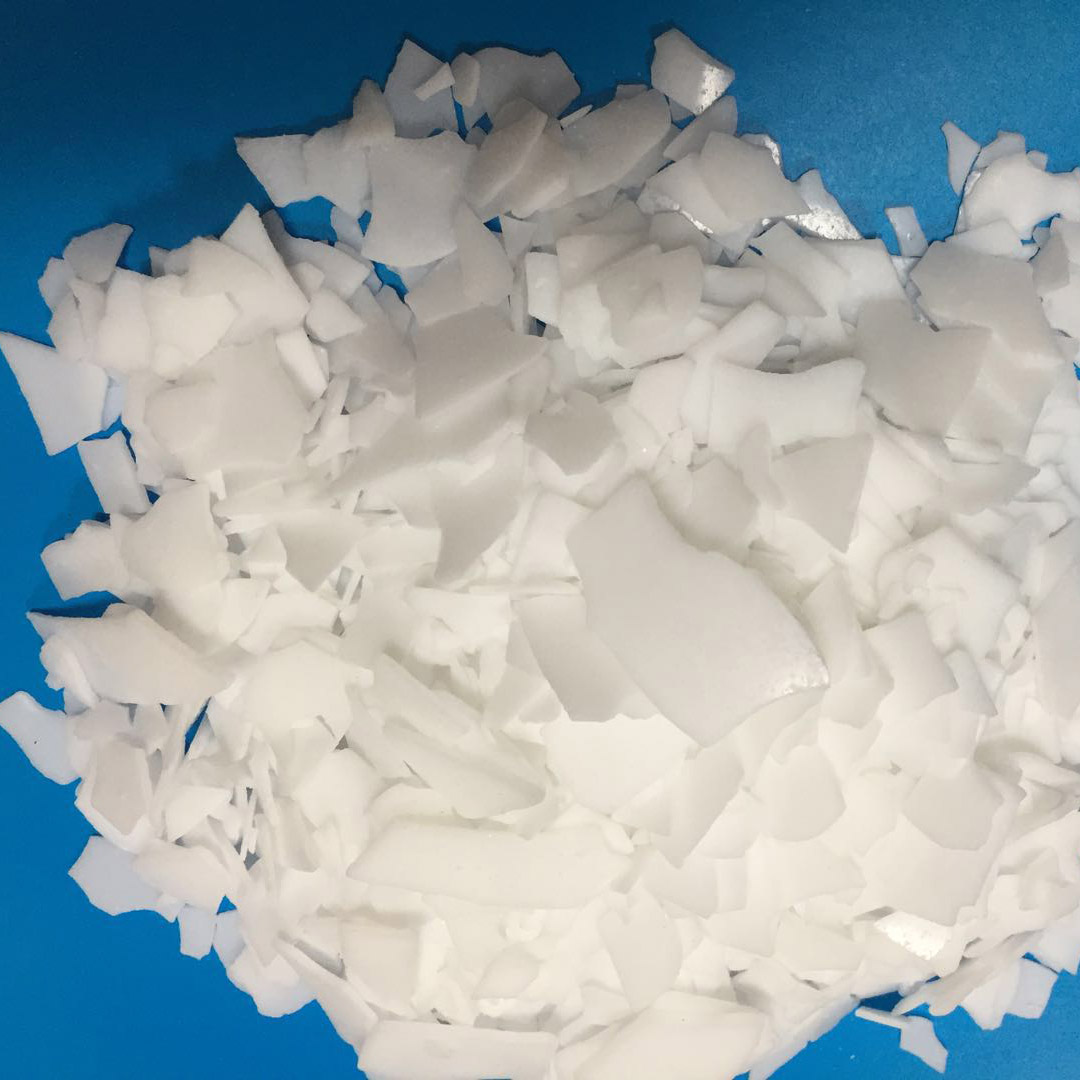

Polyethylene Wax PE

Polyethylene wax (PE wax) is a versatile and essential material that has a significant impact on various industries worldwide. Derived from the polymerization of ethylene, PE wax is known for its unique properties, including a high melting point, excellent lubricity, and chemical resistance. These characteristics make it an invaluable component in numerous applications, from plastics and coatings to cosmetics and adhesives.

Enhancing Industrial Processes

One of the primary uses of PE wax is in the plastics industry, where it serves as both a processing aid and a performance enhancer. During plastic production, PE wax improves the flow properties of molten plastic, which increases productivity and reduces energy consumption. It also minimizes the stickiness of molten plastic, protecting equipment from damage. Additionally, PE wax enhances the final product by increasing surface gloss, improving scratch resistance, and providing a smoother texture.

In the rubber and tire manufacturing sectors, PE wax acts as a processing aid, facilitating the dispersion of fillers and reinforcing agents. This improves the flow properties and mold release in tire manufacturing, leading to higher quality products.

Applications in Coatings and Adhesives

PE wax is also widely used in coatings and inks as a matting agent, which imparts a matte finish to surfaces, reduces gloss, and enhances scratch resistance. This is particularly beneficial in applications such as wood and metal coatings, as well as printing inks. In adhesives and sealants, PE wax functions as a slip agent, reducing surface friction and improving the durability of adhesive joints.

Contributions to Personal Care Products

In the personal care industry, PE wax is valued for its emollient properties. It is used in products like creams, lotions, and lip balms to provide moisturizing and softening effects, improving the texture and spreadability of these products. This makes PE wax a crucial ingredient in enhancing the quality and performance of personal care items.

Environmental Considerations

While PE wax offers numerous benefits, it is also important to consider its environmental impact. The production and disposal of polyethylene products can contribute to environmental pollution if not managed properly. However, advancements in recycling technologies and the development of biodegradable alternatives are helping to mitigate these concerns.

Future Prospects

The future of Polyethylene wax looks promising, with ongoing research and development aimed at improving its properties and expanding its applications. Innovations in production methods and the exploration of new uses in emerging industries are likely to drive the demand for PE wax even further.

conclusion

polyethylene wax plays a crucial role in enhancing the performance and efficiency of various industrial processes. Its unique properties make it a valuable material across multiple sectors, contributing to the development of high-quality products that impact our daily lives. As industries continue to innovate and address environmental challenges, the significance of PE wax is expected to grow, solidifying its position as a key component in the global market.

Click here for more info