The Versatile Role of Polyethylene Wax in Industrial Applications

Polyethylene Wax applications

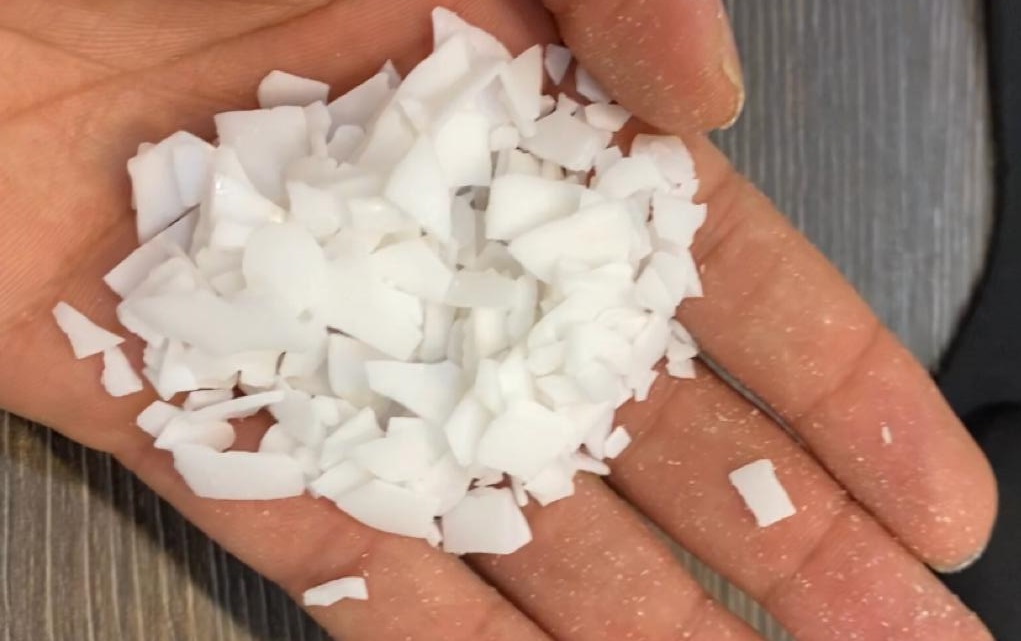

Polyethylene wax (PE wax) is a highly versatile and widely used additive in various industrial applications. Derived from ethylene, this synthetic wax boasts unique properties that make it indispensable in manufacturing processes. Let’s explore the diverse uses of polyethylene wax in factories and its impact on production efficiency and product quality.

Key Properties of Polyethylene Wax

Polyethylene wax is known for its low molecular weight, high melting point, and excellent chemical stability. These characteristics contribute to its effectiveness in various industrial applications:

Low Molecular Weight: This property ensures that PE wax remains solid but pliable at room temperature, making it easy to handle and incorporate into different processes.

High Melting Point: PE wax can withstand high temperatures, making it suitable for use in processes that require thermal stability.

Chemical Inertness: Being non-toxic and chemically inert, PE wax is safe for use in sensitive applications, including food packaging.

Applications in Plastic Manufacturing

One of the primary industries that benefit from polyethylene wax is plastic manufacturing. Here, PE wax serves multiple functions:

Processing Aid: PE wax acts as a lubricant and release agent, improving the flow properties of molten plastics. This enhancement leads to better mold filling and reduces defects such as flow lines and surface imperfections.

Surface Modifier: It is used to improve the surface gloss and appearance of plastic films, sheets, and molded parts, resulting in a smooth and shiny finish.

Impact Modifier: In certain applications, PE wax enhances the toughness and impact resistance of plastics, reducing brittleness and increasing durability.

Release Agent: PE wax facilitates the easy release of molded parts from molds, reducing sticking and improving production efficiency.

Benefits in Other Industries

Beyond plastic manufacturing, polyethylene wax finds applications in various other industries:

Coatings and Inks: PE wax is used to improve the abrasion resistance and surface properties of coatings and inks, enhancing their durability and appearance.

Adhesives: It acts as a modifier in adhesive formulations, improving their performance and application properties.

Rubber Processing: In the rubber industry, PE wax is used as a processing aid to enhance the flow and release properties of rubber compounds.

Environmental Considerations

While polyethylene wax offers numerous benefits, it is essential to consider its environmental impact. Manufacturers are increasingly focusing on sustainable production methods and the development of biodegradable alternatives to minimize the ecological footprint of PE wax.

Conclusion

Polyethylene wax is a crucial additive in various industrial applications, significantly enhancing the performance and quality of products. Its unique properties make it an invaluable component in plastic manufacturing, coatings, adhesives, and rubber processing. As industries continue to innovate and prioritize sustainability, the role of polyethylene wax will undoubtedly evolve, contributing to more efficient and eco-friendly manufacturing processes.

Click here to purchase our products ⋅