Understanding PVC Stabilizers : Ensuring Durability and Performance

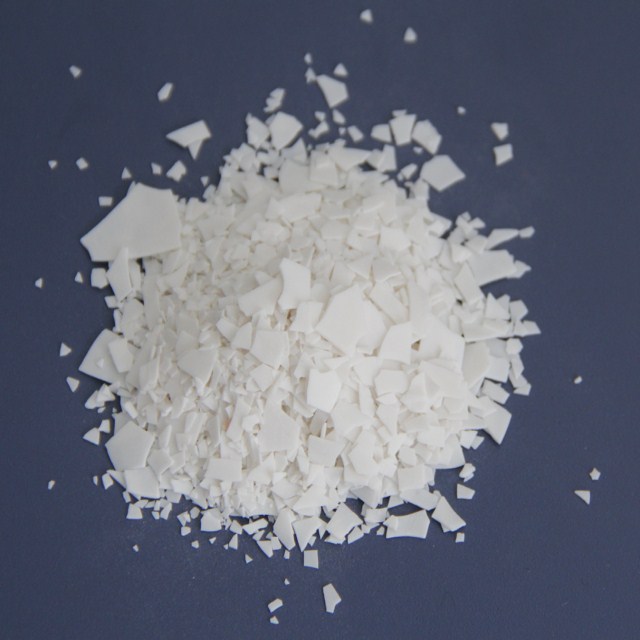

PVC stabilizers

Polyvinyl Chloride, commonly known as PVC, is a widely used thermoplastic material valued for its durability, versatility, and cost-effectiveness. However, PVC’s inherent instability under heat and light exposure necessitates the use of stabilizers to maintain its properties during processing and throughout its lifecycle.

The Role of Stabilizers in PVC

Stabilizers play a crucial role in preventing the degradation of Polyvinyl Chloride when exposed to heat and light. During processing, Polyvinyl Chloride is subjected to high temperatures, which can lead to the release of hydrogen chloride (HCl), causing discoloration and deterioration in mechanical properties. Stabilizers work by neutralizing HCl and interrupting the dehydrochlorination process, thereby preserving the integrity of the PVC material.

Types of PVC Stabilizers

There are several types of stabilizers used in PVC, each with its own mechanism of action:

Lead-based Stabilizers: Historically, lead compounds were widely used due to their effectiveness in stabilizing Polyvinyl Chloride. However, due to environmental and health concerns, their use has been significantly reduced.

Calcium/Zinc Stabilizers: These are non-toxic alternatives to lead-based stabilizers and are used in a wide range of PVC applications, particularly where non-toxicity is a requirement.

Organotin Stabilizers: These are used in applications that demand high thermal stability, such as rigid PVC used in pipes and fittings.

Organic Stabilizers: Compounds like uracil and eugenol offer an eco-friendly alternative and are being explored for their stabilizing properties in pipe production.

Benefits of Using Stabilizers

The incorporation of stabilizers in Polyvinyl Chloride not only extends its service life but also enhances its performance in various applications. Stabilized PVC exhibits improved resistance to weathering, consistent color retention, and maintains its mechanical strength over time.

PVC stabilizers in a bowl

Challenges and Innovations

The challenge in the this industry is to find stabilizers that are not only effective but also environmentally friendly. The shift towards non-toxic and sustainable stabilizers is evident, with research focusing on organic and metal-free options that can provide the necessary stability without compromising human health or the environment.

Conclusion

Polyvinyl Chloride stabilizers are essential additives that ensure the material’s performance and longevity. As the industry moves towards greener alternatives, the development of new stabilizers that are safe, efficient, and environmentally responsible will continue to be a key area of innovation.

Click here to purchase our products